Non-ferrous metals

Re-use of valuable non-ferrous metals

By definition, this fraction includes all metal alloys with a pure iron content of less than 50% and all metals other than iron. Comprising copper, aluminium, zinc, bronze, brass, lead, and gold, silver or platinum, this group thus also encompasses all white metals and precious metals. The value of the materials is comparatively high, the natural resources are limited. Their reuse is imperative, for ecological and economic reasons.

Non-ferrous metal extraction

The correct mixture of aluminium, gold, silver, platinum or copper keeps our household electronic devices running. After the useful life of the products, the numerous valuable materials in these appliance are retained in the cycle as far as possible. Electronic scrap (e.g. from small household appliances) is sorted by means of sensors and can, therefore, be re-used quickly. At SECONTRADE, you will find non-ferrous metals, the indispensable secondary raw material, at keenest prices.

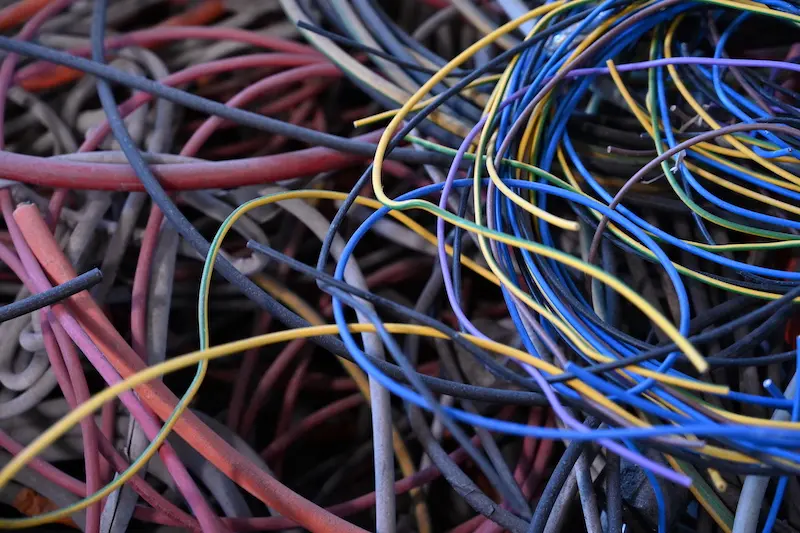

Cables as raw materials suppliers

Today, cables are virtually omnipresent: in electric appliances, buildings, and vehicles of various kinds. Each car currently incorporates about two 2 kilometres of cable, and the trend is rising further. The recycling of cables ensures that urgently needed raw materials are retained within the cycle of valuable matters. The recovery of power and data cables provides PVC, aluminium, and, above all, copper, whose content may be very high in some cables, depending on the type of the cable.

The many uses of aluminium

Aluminium is one of the most important metallic materials, second to steel only, and it is to be found everywhere. It has excellent properties in terms of flexibility, corrosion resistance, conductivity, and weight, which make it indispensable. The strength of aluminium alloys and their comparatively low weight make this material so valuable for us. At 47%, the largest area of use is the construction of vehicles, ships, aeroplanes, and rail vehicles. (Source: Aluminium Deutschland e. V.) In addition, certain components and light-weight cables are made from aluminium, as are tinfoil, coffee capsules, cans, and many other items.

Recycling of aluminium

The recycling of aluminium saves energy, reduces CO2 emissions and conserves resources at the same time (Source: www.alu.ch). Europe exports about 515,000 tonnes of aluminium waste (Source: European Aluminium). In aluminium production, as much as 80 % of primary materials are replaced by aluminium scrap (2019: 366,300 t) with 95 % energy savings compared to primary materials. For example, aluminium can be recycled again and again and used for new applications, so about 75 % of the aluminium ever extracted is still in use.

Source: Bundes Abfallwirschaftsplan 2022 S.405Copper is not to be dispensed with

This non-ferrous metal is one of the most important raw materials of our time. In terms of electric conductivity, it is second only to silver (which is a lot more expensive). Copper is also an optimal heat conductor. Thanks to its properties, it is to be found nearly everywhere.

No future without copper

Copper has been used for 10,000 years, and the modern technology without this metal is unthinkable. Copper is driving the energy transition: a wind power station requires up to 8 tonnes of copper. About 100 kgs of copper are needed for an electric car, approximately twice as much as for a car with an internal combustion engine. The demand will further increase with the progress of electromobility.

Recycling rate of copper: approx. 50%

In reality, copper is recycled almost in its entirety. If one assumes the average useful life of copper to be 35 years, the rate will go up.

Real recycling rate of copper: approx. 80 %.

Treatment without loss of quality

Copper does not lose its value, and a closed cycle pays off especially in this case. Recycled copper has the same properties as the primary material. Today, copper already has high recycling rates.